Burning lime through the night

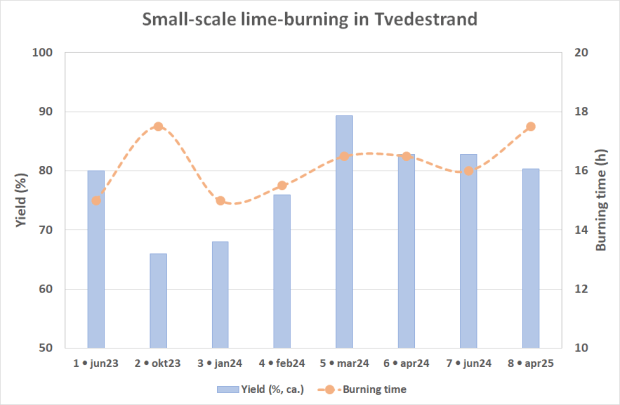

Over the past 10 years small-scale lime burning has become a new tradition in Norway. Aimed at repair and conservation of old buildings, especially churches, lime is now burnt at 7-8 places across the country: in Mid-Norway, on the west coast and in the Hamar region in the southeast. In Tvedestrand, on the south coast, we began burning in a half-ton kiln two years ago. Here are impressions from our 8th burn this spring.

Having designed and operated three lime kilns with friends and colleagues on the west coast from 2016 on, in 2022 I met Anders Oppegaard after moving to the south. We designed a new half-ton kiln, Anders built it and since then we have produced small quantities of traditional quicklime (lump lime) for conservation. The kiln is operated by Anders’ small masonry company, which he runs with his son Henrik. I take part in most aspects of the project, with emphasis on raw material selection, quality control of quick lime and hotmixed mortars, as well as optimizing the firing process.

Though the design is based on age-old principles (Roman, medieval), the down-scaled, wood-fired kiln is built from modern materials, mainly refractory bricks set in clay mortar.

We usually burn relatively pure contact-metamorphic limestone, in effect a medium-fine-grained marble, from a deposit in Brevik, some 100 km east of Tvedestrand. The small kiln is easily loaded. Yet it takes a few hours, since it is vital to take care in the process: Larger stones at the bottom, sucessively smaller ones towards the top. We also use several holes through the load to maintain a good draught.

The limestone load is placed on a self-supporting vault, also made from limestone, which is constructed using supporting ribs of refractory bricks. The ribs remain in the kiln during the firing process, as a security measure – if the vault is poorly built and may collapse. Fortunately, we have never experienced collapse.

Fire is usually lit in the morning and during the first 5-7 hours the aim is to slowly increase the temperature, first to drive off moisture. This is the time for my daughter Lotta to repair small damages on the kiln exterior!

When the load and the kiln are thoroughly dry and the draught excellent, the top is successively covered, and a “chimney” is made from bricks to “raise” the fire. Covering the kiln too early may cause a poor draught and difficulties in raising the temperature to the necessary 850-900 degrees at the top.

We don’t measure temperature but rely on nearly 10 years of experience with small-scale lime kilns in controlling the burn. Slowly, the glow in the limestone load increases towards the top, and changes from red to orange to yellow.

When the glow on the top is close to yellow and the flames sometimes show a bluish tint, we know that some 900 degrees have been reached, and the burn is almost finished. Yet, it may take quite long to get the topmost limestone lumps thoroughly burnt. On finishing, we close the kiln and let the fire die out through the rest of the night and the following morning.

In the following afternoon, the kiln is still hot, but cold enough for emptying. We maintain strict quality control and all lumps are broken by hammer to inspect the “core” and look for impurities. When lumps are not thoroughly burnt, even showing only very small “cores”, they are sorted out and can be used for e.g. pinning in deep/large masonry joints. The good lumps are stored in air-tight 60 litre barrels.

The April 2025 burn went reasonably well. The weather was excellent for lime burning, with only moderate winds. However, we used mixed firewood of rather inferior quality, since we wanted to “burn it all up”, and make a fresh start the next time. With high quality firewood (dry pine!) the yield, quicklime without cores, would probably have been up some 10%.

Lime from the April 2025 burn was used in a practical lime mortar masonry course at Tanum medieval church in Larvik in the beginning of May. Previously, our lime has been used for full restoration works at e.g. Hedrum medieval church, also in Larvik.

Further reading about lime burning on this website

- https://per-storemyr.net/tag/kalk (some articles in English, most in Norwegian)

Discover more from Per Storemyr Geoarchaeology & Conservation

Subscribe to get the latest posts sent to your email.

Pingback: “Signature WS“ from United Alabaster